Asphalt Milling & Full-Depth Reclamation Services in Greater Cincinnati

Improve Pavement Performance with Expert Milling & Reclamation in Cincinnati, Lawrenceburg, Independence & Beyond

With years of experience serving commercial, municipal, and industrial clients, our paving team proudly specializes in asphalt milling and full-depth reclamation (FDR)—two cost-effective methods that restore aging or damaged pavement without the costly reconstruction.

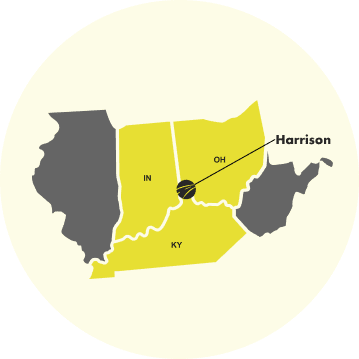

Cincinnati Asphalt is proud to provide high-performance pavement restoration solutions across:

- Greater Cincinnati

- Dayton

- Independence

- Lawrenceburg

- Southeast Indiana

- Northern Kentucky

Whether you’re dealing with surface wear or structural failure, we tailor our solutions to your budget, timeline, and long-term durability needs. These techniques are ideal for parking lots, roadways, industrial yards, and more in the Greater Cincinnati area.

What is Asphalt Milling?

Asphalt milling is the process of grinding up and removing the top layers of worn or damaged asphalt pavement without disturbing the underlying base. This method preserves the structural integrity of your pavement while preparing the surface for a fresh layer of asphalt.

Not only is milling a budget-conscious and eco-friendly solution, but it also helps extend the life of your pavement while minimizing disruptions to your operations.

Benefits of Asphalt Milling

Extends Pavement Lifespan

Refreshes the surface without needing full-depth removal, helping delay costly full-depth replacements.

Environmentally Friendly

The millings can be brought to an asphalt plant to be recycled and reused, reducing waste and supporting sustainability goals.

Minimizes Disruption

Faster and less invasive than full reconstruction, allowing traffic flow and operations to resume quickly.

Cost-Effective

Offers significant savings compared to full pavement replacement, making it ideal for budget-conscious property managers.

Our Pavement Milling Process

Cincinnati Asphalt uses modern, high-performance equipment to ensure smooth and precise results with every project. Here’s what to expect:

Site Assessment

Our trained experts inspect your paved surfaces, assessing for signs of damage or underlying vulnerabilities.

Surface Cleaning

We then fully clean any debris from the surface to prepare for the milling process

Asphalt Milling

Specialized milling machines grind off the surface layer to a predetermined depth.

Surface Repair

Any irregularities or damaged spots in the milled surface are repaired or reinforced.

Asphalt Installation

Our asphalt paving crew installs and compacts a new layer of hot mix asphalt for a refreshed, durable finish.

Finishing Touches

Our team adds professional line striping, ADA-compliant markings, and signage as needed, ensuring paved surfaces are ready for safe usage.

Start Your Asphalt Milling or Reclamation Project Today

What is Full-Depth Reclamation (FDR)?

Full-depth reclamation is a powerful pavement rehabilitation method that rebuilds the structural foundation of a failing surface. Rather than simply grinding off the top layer like milling, FDR pulverizes both the existing asphalt and underlying base materials, mixing them to create a new, stabilized sub-base.

This technique is ideal for roads or parking lots suffering from deep structural damage, such as widespread cracking, potholes, or failed drainage.

By recycling existing materials, full-depth reclamation drastically reduces the need for hauling and new aggregate, making the process not only cost-effective but also sustainable.

Benefits of Full-Depth Reclamation

Full-depth reclamation is a smart, long-term solution for severely compromised pavement. Its key benefits include:

Lasting Durability

Rebuilding the base ensures greater structural support and resistance to future cracking or rutting.

Reduces Waste & Hauling Costs

Pulverizing and reusing the existing pavement eliminates the need for off-site material disposal or expensive new base material.

Eco-Friendly

Reclaims 100% of existing materials, reducing your project’s environmental footprint.

Cost Effective

Achieves the benefits of complete reconstruction without the high costs and extended timelines of full removal and rebuild.

This method is commonly used in industrial parks, municipal roads, and parking areas where longevity is a top priority.

Our Reclamation Process

We follow a precise, engineered process to ensure a stable, high-performing result.

This approach transforms failed pavement into a stronger, more resilient surface, ready to withstand traffic and weather for years to come.

Pulverization

Our equipment grinds both the existing asphalt and base to form a consistent blend.

Blending & Grading

The pulverized material is mixed to the proper moisture content and graded for evenness and slope.

Compaction

A new base is compacted using rollers to create a solid foundation.

Top Layer Installation

A new top layer of asphalt is installed, followed by compaction, line striping, and any required safety features.

How to Know Which Option is Right for Your Property

Choosing between asphalt milling and full-depth reclamation depends on your pavement’s condition, budget, and your long-term goals. While both methods are designed to extend pavement life and reduce costs, they address very different issues.

Here’s how to determine which solution is the best fit for your property.

Signs That Milling is the Right Choice

Milling is the best choice for you if your pavement shows signs of wear on the surface, but the sub-base remains stable:

- Surface-level cracking or raveling

- Uneven patches from previous repairs

- Minor drainage issues

- Need for budget-friendly resurfacing with minimal disruption

- Pavement is still structurally sound underneath

This makes milling ideal for commercial parking lots, light-duty roadways, and municipal surfaces that require improved appearance and drivability without total rebuild.

Signs That Full-Depth Reclamation is Best

Full-depth reclamation is typically the better option when deeper structural issues are present:

- Widespread alligator cracking or potholes

- Sub-base movement or instability

- Soft spots that indicate foundation failure

- Long-term goals for durability and sustainability

- Need to eliminate deep drainage or utility issues under the surface

This approach is often used on heavy-duty pavements that carry high traffic volumes or need to meet long-term usage requirements.

Extend Pavement Life with Cincinnati Asphalt’s Milling & Reclamation Services

Whether your pavement needs a surface refresh or a full structural rebuild, Cincinnati Asphalt delivers efficient, cost-effective solutions tailored to your site conditions.

Our asphalt milling and full-depth reclamation services are designed to maximize your investment, reduce future maintenance costs, and minimize environmental impact.

We proudly serve businesses, municipalities, and industrial facilities across:

- Greater Cincinnati

- Dayton, OH

- Independence, KY

- Lawrenceburg, IN

- Southeast Indiana

- Northern Kentucky

From HOAs to schools and healthcare facilities, we’ve helped clients in various industries improve their pavement with expert planning and flawless execution.

Reclaim your paved surfaces today. Contact Cincinnati Asphalt for a custom quote or site evaluation and discover how our restoration methods can extend the life of your asphalt while staying within your budget.

Our Service Areas

Our Office:

- Harrison